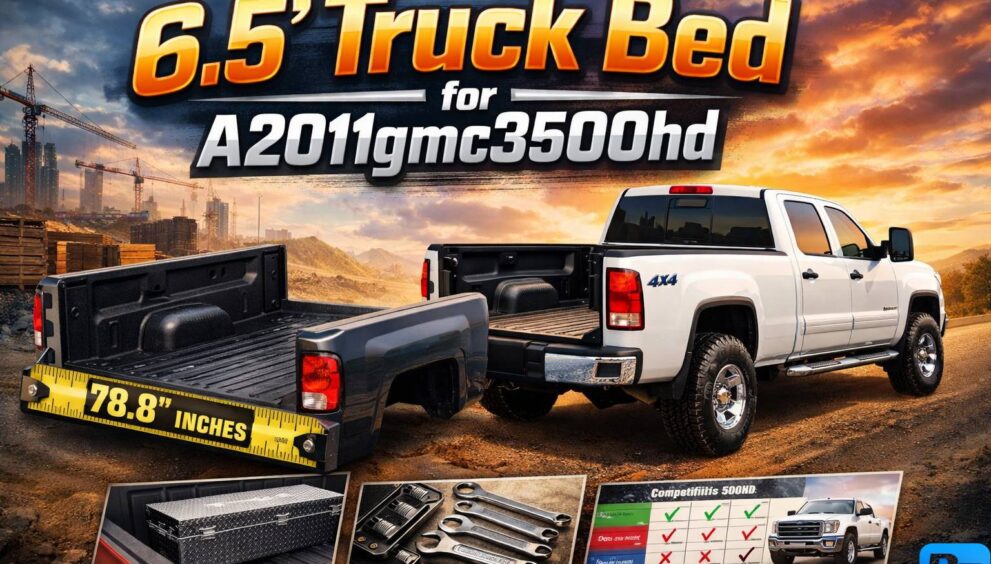

6.5’ Truck Bed for A2011gmc3500hd

When evaluating the 6.5’ Truck Bed for A2011gmc3500hd, it is essential to understand both the factory specifications and the real-world applications of this configuration. The 2011 heavy-duty pickup lineup was engineered for durability, towing capacity, and cargo versatility, and the short bed configuration offers a balance between maneuverability and functionality. Many buyers, mechanics, and truck owners search for this specific bed size to determine compatibility, replacement options, or modifications.

This guide provides a technical and structured breakdown of bed dimensions, compatibility factors, installation processes, and practical usage scenarios. Whether you are a fleet manager, truck enthusiast, or parts reseller, this article is designed to deliver accurate, actionable insights to help you make informed decisions.

What Are the Specifications of the 6.5 ft Truck Bed?

The 6.5-foot truck bed is often referred to as the “standard” or “short” bed configuration in heavy-duty pickup trucks. In the 2011 model year, this bed size typically measures approximately 78.8 inches in length, providing a balance between cargo capacity and overall vehicle length. This configuration is commonly paired with crew cab or extended cab models, making it a practical choice for both work and daily driving.

From a dimensional standpoint, the bed width at the floor is generally around 50.5 inches between the wheel wells, allowing standard construction materials such as plywood sheets to be transported with minimal constraints. The depth of the bed is engineered to support moderate payloads while maintaining ease of loading and unloading. These measurements are critical when selecting liners, covers, or replacement parts.

The cargo volume of a 6.5 ft bed typically reaches approximately 60 to 62 cubic feet. This capacity supports various applications, including transporting tools, equipment, or recreational gear. The structure is reinforced with high-strength steel panels designed to withstand heavy loads and harsh working conditions.

Another key aspect is the integration of tie-down points and bed rail systems. These features enhance load security and allow for customization through accessories such as racks, toolboxes, and tonneau covers. Understanding these specifications is essential for anyone planning to upgrade or replace their truck bed.

How Does Compatibility and Fitment Work?

Compatibility is one of the most critical factors when dealing with truck bed replacements or modifications. The 6.5 ft bed is not universally interchangeable across all models, even within the same brand. Factors such as frame design, mounting points, and wiring harness configurations must be carefully evaluated before proceeding with a swap.

In general, truck beds from similar model years within the same generation are more likely to be compatible. For example, models produced between 2007 and 2013 often share structural similarities. However, differences in trim levels, drivetrain configurations, and manufacturing variations can still impact fitment accuracy.

Electrical integration is another important consideration. Modern truck beds often include integrated lighting systems, sensors, and tailgate electronics. Ensuring that these components align with the vehicle’s existing wiring harness is crucial to avoid functional issues or safety risks.

A practical approach to verifying compatibility includes measuring mounting points, comparing part numbers, and consulting manufacturer specifications. Professionals often recommend performing a dry fit before final installation to confirm alignment and avoid costly adjustments.

Why Choose a 6.5 ft Bed Over an 8 ft Bed?

The decision between a 6.5 ft bed and a longer 8 ft bed depends on intended use and operational requirements. The shorter bed offers improved maneuverability, making it easier to navigate urban environments, tight job sites, and parking spaces. This is particularly beneficial for drivers who use their trucks for both work and personal transportation.

Weight distribution is another advantage of the shorter bed configuration. With a reduced overall length, the vehicle may experience improved handling characteristics, especially when driving without a full load. This can contribute to a more comfortable and controlled driving experience.

However, the trade-off comes in cargo capacity. An 8 ft bed provides significantly more space for hauling large or bulky items, making it more suitable for heavy-duty commercial applications. Contractors and fleet operators often prefer longer beds for transporting construction materials or large equipment.

Ultimately, the choice depends on balancing practicality and capacity. The 6.5 ft option is ideal for users who need versatility, while the longer bed is better suited for maximum hauling requirements. Understanding these differences helps users select the most appropriate configuration for their needs.

How to Replace or Install a Truck Bed

Replacing or installing a truck bed requires careful planning and the right set of tools. The process typically begins with removing the existing bed, which involves disconnecting electrical components, unbolting mounting hardware, and lifting the bed off the frame. Using proper lifting equipment is essential to ensure safety and prevent damage.

Once the old bed is removed, the frame should be inspected for rust, damage, or misalignment. Addressing these issues before installation ensures a stable and secure fit for the new bed. This step is often overlooked but is critical for long-term durability and performance.

The new bed should then be positioned onto the frame, aligning mounting points accurately. Bolts must be tightened according to manufacturer specifications to maintain structural integrity. Electrical connections, including tail lights and sensors, should be reattached and tested for proper functionality.

A final inspection should be conducted to verify alignment, stability, and operational readiness. This includes checking for gaps, ensuring the tailgate operates smoothly, and confirming that all accessories are securely installed. Following a systematic approach minimizes errors and ensures a professional-quality installation.

Why Maintenance and Accessories Matter

Maintaining a truck bed is essential for preserving its structural integrity and appearance. Regular cleaning helps prevent corrosion, especially in environments exposed to moisture, salt, or chemicals. Applying protective coatings or liners can significantly extend the lifespan of the bed.

Accessories play a crucial role in enhancing functionality. Bed liners protect against scratches and dents, while tonneau covers provide security and weather protection. Toolboxes and storage systems improve organization and efficiency, particularly for professional users.

Load management is another important aspect of maintenance. Using tie-down straps and anchors ensures that cargo remains secure during transport. Improper load distribution can lead to damage or safety hazards, making proper securing techniques essential.

Periodic inspections should be conducted to identify signs of wear, such as rust, loose bolts, or damaged panels. Addressing these issues early prevents costly repairs and maintains the overall performance of the truck bed. A well-maintained bed not only improves usability but also retains resale value.

FAQs

1. What is the exact size of the 6.5’ Truck Bed for A2011gmc3500hd?

The bed typically measures approximately 78.8 inches in length, with a width of around 50.5 inches between the wheel wells and a cargo volume of about 60 cubic feet.

2. Can a truck bed from another model year fit this truck?

Beds from the same generation (around 2007–2013) may fit, but compatibility depends on mounting points, wiring, and trim differences.

3. Is the 6.5 ft bed suitable for heavy-duty work?

Yes, it can handle moderate workloads, but for maximum cargo capacity, an 8 ft bed is generally more suitable.

4. What tools are required for installation?

Basic tools include socket sets, wrenches, lifting equipment, and electrical connectors for safe and proper installation.

5. How can I protect my truck bed from damage?

Using bed liners, covers, and proper load securing methods helps prevent scratches, dents, and corrosion.