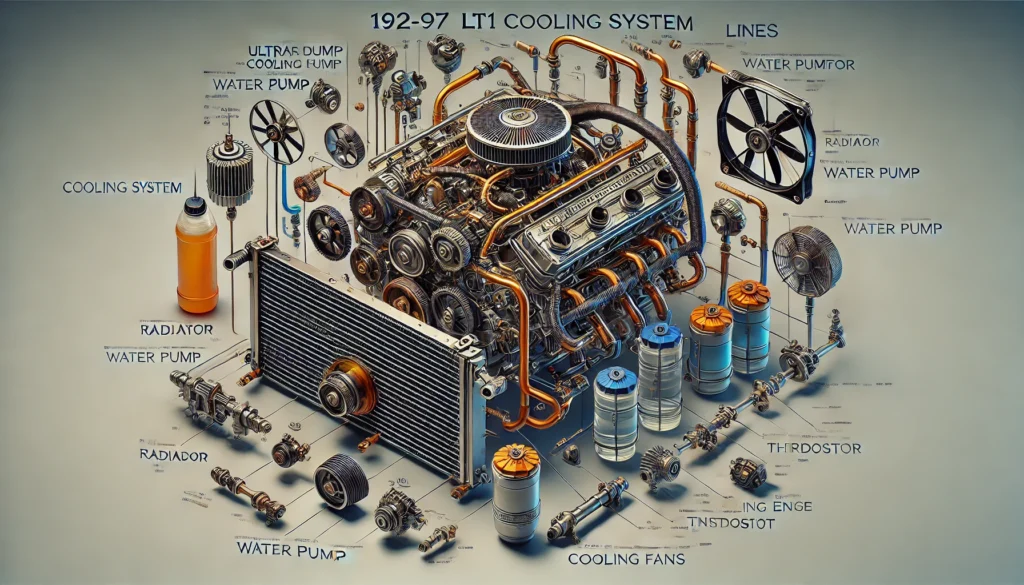

The 192-97 LT1 cooling system is designed for the LT1 engine, which was popular in various Chevrolet models from 1992 to 1997. This cooling system is crucial for maintaining optimal engine temperatures, ensuring reliable performance and longevity.

The LT1 engine utilizes a liquid cooling system that circulates coolant through the engine to absorb heat. It then transfers this heat to the radiator, where it dissipates into the air.

Understanding how the cooling system functions is essential for effective maintenance and troubleshooting. Proper functioning of the cooling system prevents overheating, which can lead to severe engine damage.

Overall, the cooling system plays a vital role in the engine’s performance, efficiency, and durability.

Important Parts of the Lines of the 192-97 LT1 Cooling System

The key components of the 192-97 LT1 cooling system lines include the radiator, water pump, coolant reservoir, and various hoses. Each component works together to ensure efficient coolant circulation throughout the engine.

- Radiator: The radiator dissipates heat from the coolant as it flows through, helping to maintain a safe operating temperature.

- Water Pump: This pump circulates the coolant through the engine and radiator, ensuring a continuous flow.

- Coolant Reservoir: This container holds excess coolant and allows for easy monitoring of coolant levels.

Understanding these components is essential for diagnosing cooling system issues and performing maintenance. Properly functioning components contribute to an efficient cooling system.

What Are the Functions of the 192-97 LT1 Cooling System Lines?

The functions of the 192-97 LT1 cooling system lines are crucial for maintaining optimal engine temperature. The primary function is to transport coolant to and from the engine and radiator.

As the engine generates heat, the coolant absorbs this heat and carries it to the radiator. Here, the heat dissipates into the air, allowing the coolant to return to the engine at a lower temperature.

Additionally, the cooling system lines help maintain consistent engine temperatures, improving fuel efficiency and performance. Efficient heat management also minimizes the risk of engine damage caused by overheating.

In summary, the cooling system lines are integral to the overall function of the LT1 cooling system.

Common Issues with 192-97 LT1 Cooling System Lines

Common issues with the 192-97 LT1 cooling system lines can lead to serious engine problems if not addressed promptly. One frequent issue is leaks in the coolant lines, which can occur due to wear, corrosion, or damage.

- Overheating: A reduction in coolant levels can lead to engine overheating, which may cause severe damage.

- Clogged Lines: Debris can accumulate in the cooling lines, obstructing coolant flow and reducing efficiency.

- Hose Deterioration: Over time, hoses can become brittle or cracked, compromising the cooling system’s integrity.

Regular inspection and maintenance can help identify these issues early, ensuring the cooling system operates effectively.

How to Maintain the 192-97 LT1 Cooling System Lines

Maintaining the 192-97 LT1 cooling system lines is essential for ensuring reliable engine performance. Regular inspections are crucial to identify signs of wear, corrosion, or damage to the cooling lines and hoses.

It’s also important to check the coolant levels and quality regularly. Ensure that the coolant is at the recommended level and that it meets the manufacturer’s specifications. Flushing the cooling system periodically helps remove any debris or contaminants that may have accumulated.

- Hose Replacement: Replace any worn or damaged hoses to prevent leaks.

- Coolant Replacement: Change the coolant according to the manufacturer’s recommendations to ensure optimal performance.

Following these maintenance tips can help extend the life of the cooling system and prevent costly repairs.

Upgrading the 192-97 LT1 Cooling System Lines for Performance

Upgrading the 192-97 LT1 cooling system lines can enhance overall engine performance and reliability. Aftermarket cooling lines often feature improved materials that resist heat and corrosion, offering better durability than stock components.

Performance-oriented upgrades may include larger diameter hoses, which can improve coolant flow and reduce the risk of overheating. Upgrading the radiator to a high-performance model can also enhance cooling efficiency, especially in high-performance applications.

Additionally, consider installing a more powerful water pump to improve coolant circulation, particularly in modified engines that generate more heat. These upgrades can contribute to a more efficient cooling system and improved engine performance.

What Are the Benefits of Properly Functioning 192-97 LT1 Cooling System Lines?

Properly functioning 192-97 LT1 cooling system lines offer numerous benefits that contribute to the overall performance and longevity of the engine. One primary benefit is preventing overheating, which can cause severe engine damage and costly repairs.

Efficient cooling lines help maintain optimal engine temperatures, improving fuel efficiency and performance. This efficiency leads to smoother engine operation, enhancing the driving experience.

Additionally, a well-maintained cooling system reduces the risk of coolant leaks, which can lead to environmental concerns and loss of engine power. In summary, properly functioning cooling system lines are essential for a reliable and efficient LT1 engine.

Installation Guide for 192-97 LT1 Cooling System Lines

Installing the 192-97 LT1 cooling system lines requires careful attention to detail to ensure proper functionality. Start by gathering the necessary tools, including wrenches, pliers, and coolant.

Begin the installation by draining the existing coolant from the system. Remove any old or damaged lines and clean the connection points to ensure a secure fit for the new lines.

- Attach New Lines: Carefully attach the new cooling lines, ensuring that all connections are tight to prevent leaks.

- Refill Coolant: Once the installation is complete, refill the cooling system with the appropriate coolant mixture.

- Bleed the System: Run the engine to allow the coolant to circulate, then bleed any air from the system for optimal performance.

Following these steps will help ensure a successful installation of the cooling system lines.

Comparing 192-97 LT1 Cooling System Lines with Other Cooling Systems

When comparing 192-97 LT1 cooling system lines with other cooling systems, several factors come into play. The LT1 cooling system is designed specifically for the LT1 engine, providing optimal performance for this particular setup.

In contrast, traditional cooling systems may use larger radiators or more complex configurations, which can lead to increased weight and complexity. The LT1 system is streamlined, making it easier to maintain and install in compatible vehicles.

Another aspect is the material used in the cooling lines. The LT1 lines are often constructed from durable materials that resist heat and corrosion, ensuring long-lasting performance compared to standard systems.

Overall, the design and material quality of the 192-97 LT1 cooling system lines provide specific advantages tailored to LT1 engines.

Troubleshooting 192-97 LT1 Cooling System Lines Problems

Troubleshooting problems with the 192-97 LT1 cooling system lines is essential for maintaining engine performance. Common symptoms to watch for include overheating, coolant leaks, and poor engine performance.

If the engine is overheating, start by checking the coolant levels and looking for any visible leaks in the cooling lines. Inspect hoses for signs of wear, such as cracks or bulges, which may indicate the need for replacement.

If coolant leaks are present, locate the source and determine whether the lines need to be repaired or replaced. Conduct a pressure test to identify any hidden leaks that may not be immediately visible.

By following these troubleshooting steps, you can identify and address issues with the cooling system lines before they lead to more significant problems.

Future Trends in Cooling System Technology for LT1 Engines

The future of cooling system technology for LT1 engines is likely to see several advancements aimed at improving efficiency and performance. Innovations in materials, such as lightweight composites, may help reduce the weight of cooling system components while enhancing durability.

Increased automation and electronic controls may also play a role in future cooling systems, allowing for more precise temperature management. Smart cooling systems could use sensors to monitor engine temperatures and adjust coolant flow dynamically for optimal performance.

Additionally, as emissions regulations become more stringent, improved cooling solutions will be essential to ensure that LT1 engines continue to operate efficiently while meeting environmental standards.

Conclusion: The Importance of 192-97 LT1 Cooling System Lines

In conclusion, the 192-97 LT1 cooling system lines are vital for maintaining optimal engine performance and reliability. They facilitate efficient coolant circulation, helping to prevent overheating and prolong the life of the engine.

Proper maintenance, timely upgrades, and a thorough understanding of these lines can significantly enhance the performance of LT1 engines. As technology continues to evolve, keeping up with trends in cooling systems will be essential for enthusiasts and mechanics alike.

Ultimately, ensuring the cooling system lines are in good condition is critical to achieving the best performance from the LT1 engine, making them a key focus for any vehicle owner.